Façade design in the UAE has moved fast over the last decade. Expectations have moved even faster.

Architects and engineers are now expected to meet increasingly strict U-value requirements, work within limited wall thicknesses, and still deliver façades that are visually strong, all while designing for some of the harshest climatic conditions in the world.

This is where nano-insulation material is getting serious attention.

Nano-insulation is different from conventional insulation because it works at the material science level. Instead of needing thick layers, it provides great thermal performance in very thin applications. This makes it perfect for modern façade systems, especially in high-rise and projects that care a lot about design.

In high-rise towers or projects where space and design are important, thick or multiple insulation layers cannot always be feasible, especially when façade depth, detailing, and aesthetics are tightly controlled. Nano-insulation in the UAE is a better choice when architects want to meet performance targets without compromising the architectural intent.

To continue this discussion, we’re gonna talk about why nano-insulation material is emerging as one of the best solutions for façades, how it compares to conventional insulation approaches, and how UAE consultants are reviewing products like I-GK2 for projects with tight performance thickness limitations.

What Is Nano-Insulation Material?

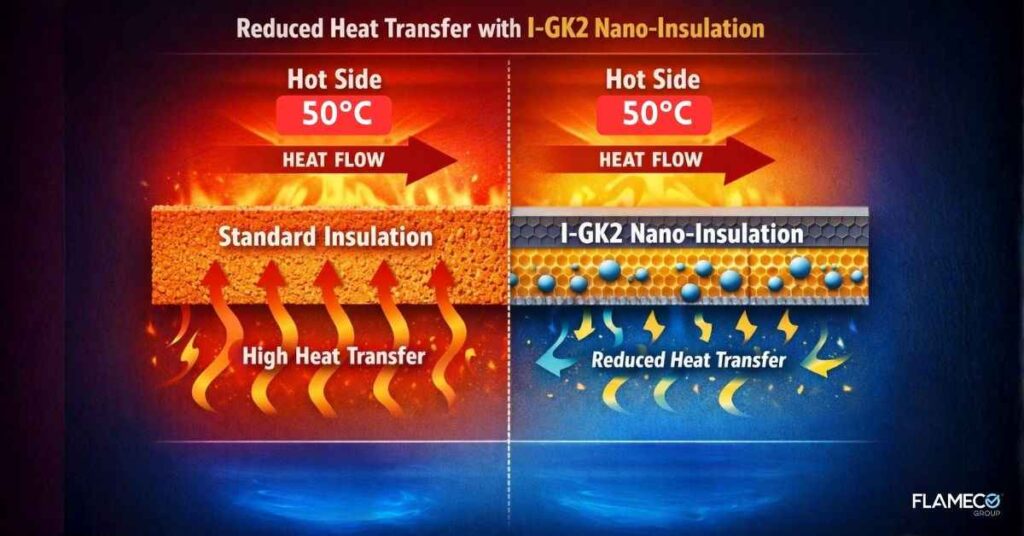

Nano-insulation material refers to insulation products that use nanotechnology for thermal insulation at a microscopic level. Rather than relying on thick layers of trapped air. These materials are engineered with microstructures that dramatically reduce thermal conductivity.

Instead of trapping air in thick layers (like EPS, XPS, or mineral wool), nano-insulation controls heat flow by:

- Reducing thermal conductivity at a molecular level

- Minimizing convection and radiation

- Delivering performance through material science rather than bulky layers

This makes nano-insulation in UAE projects particularly suitable where space, weight, and façade detailing are critical.

Why Façade Systems Need a New Insulation Approach

Traditional façade insulation systems face several challenges in the UAE:

- Increasing wall thickness to meet lower U-values

- Conflicts between insulation depth and architectural detailing

- Added structural load from heavy insulation materials

- Reduced usable floor area in high-rise developments

For many architects, the issue isn’t insulation availability; it’s insulation practicality.

This is where nano-insulation material becomes relevant.

Nano-Insulation vs Conventional Insulation for Façades

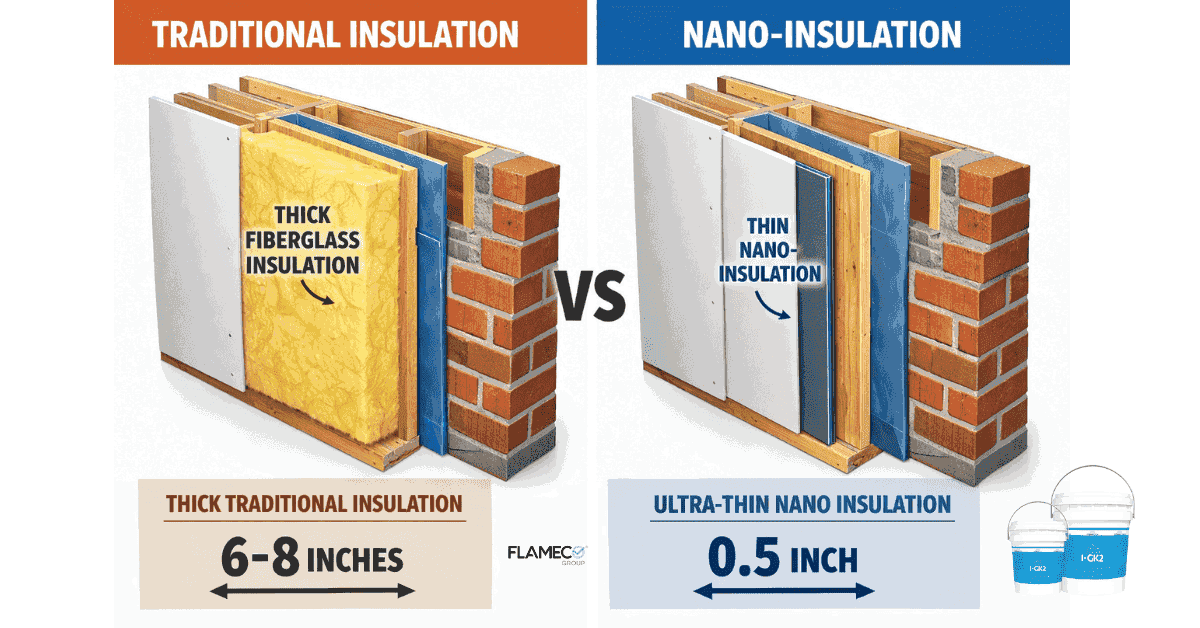

Thickness Comparison

Conventional systems often require:

- 60–100 mm insulation layers to approach strict U-value targets

Nano-insulation material can achieve similar thermal resistance with:

- Significantly reduced thickness, considering I-GK2, sometimes under 20 mm

This opens new design possibilities for façade engineers.

Design Flexibility

With nano-insulation:

- Slim façade build-ups become feasible

- Retrofit and refurbishment projects are easier to execute

- Architectural proportions remain untouched

This is especially useful in UAE high-rise and mixed-use developments where façade depth is tightly controlled.

Nanotechnology for Thermal Insulation in UAE Climate

The UAE climate creates unique challenges for engineers:

- Extreme summer temperatures

- High solar radiation

- Large temperature differentials between interior and exterior

Nano-insulation material performs well in such environments because:

- It maintains thermal performance under high heat exposure

- It reduces thermal bridging in façade assemblies

- It supports compliance with UAE energy efficiency regulations

This makes nanotechnology for thermal insulation increasingly attractive for consultants focused on long-term building performance.

Role of Nano-Coating in Façade Insulation

Some nano-insulation solutions function as advanced nano-coatings, applied directly to façade substrates.

Benefits include:

- Easy integration with existing wall systems

- Reduced installation difficulties

- Compatibility with various façade finishes

In façade retrofits, nano-coating insulation can be especially valuable where removing or thickening existing walls is not an option.

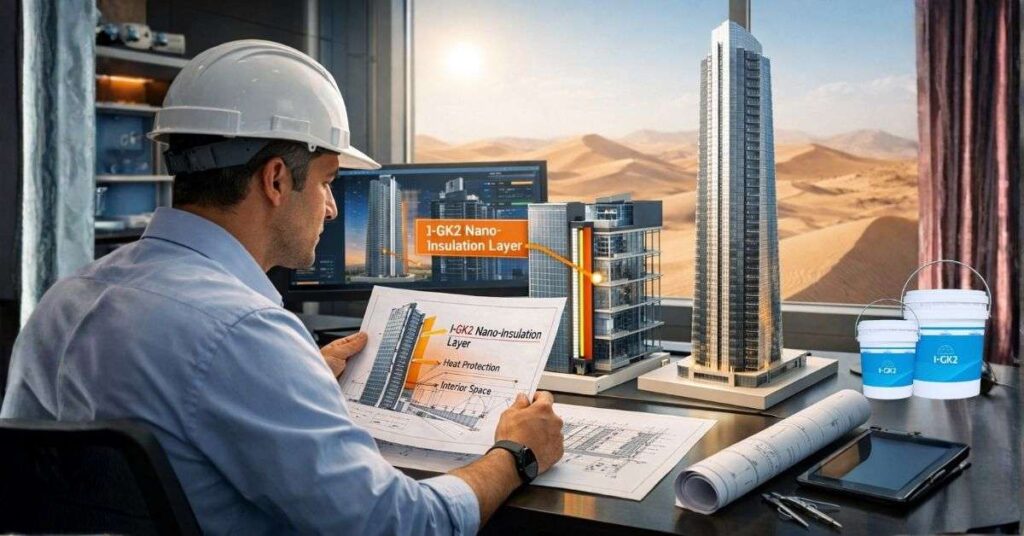

Where I-GK2 Fits into Nano-Insulation Applications

I-GK2 is evaluated as a nano-insulation material because of its ultra-low thermal conductivity and minimal thickness requirements.

The following are the benefits it offers to façade designers:

- A way to achieve low U-values targets without increasing wall thickness

- Greater freedom in façade detailing

- A solution for projects where traditional insulation systems have spatial or structural limitations

Rather than attempting to replace every insulation method, I-GK2 is typically evaluated in scenarios where conventional solutions start to hit their limits. This is especially true in performance-driven façade designs, where space constraints, thermal targets, and architectural detailing leave little room for traditional insulation approaches to perform effectively.

When Does Nano-Insulation Make Sense for Façades?

Nano-insulation material becomes particularly relevant when:

- Wall thickness is capped by design constraints

- Façade retrofitting is required

- High thermal performance is needed in slim assemblies

- Architectural intent must not be compromised

For UAE architects and engineers, these conditions are no longer edge cases. They’re showing up project after project, turning nano-insulation from a niche solution into a practical design consideration.

Final View

As façade performance requirements tighten across the UAE, nano-insulation material is no longer just a new concept. It’s a practical response to very real design constraints.

Rather than thickness, nano-insulation delivers thermal efficiency through material science and allows architects and engineers to rethink façade build-ups without sacrificing performance or aesthetics.

Products like I-GK2 are now being considered not as replacements for traditional insulation, but as strategic tools for situations where conventional systems no longer meet expectations.

When façade depth, design freedom, and U-value targets collide, nano-insulation is quickly becoming one of the most relevant conversations in modern building design.