Thermal insulation in the UAE has become one of the most important design and engineering priorities. With scorching temperatures, strict green building codes, and rising energy-efficiency demands, architects, consultants, and contractors must choose the right insulation from the very beginning of the project.

This guide explains everything you need to know about thermal insulation in the UAE, including U-values, materials, regulations, approximate costs, use cases, best practices, and a new technology in the UAE for thermal insulation with a thin layer.

What Is Thermal Insulation in the UAE?

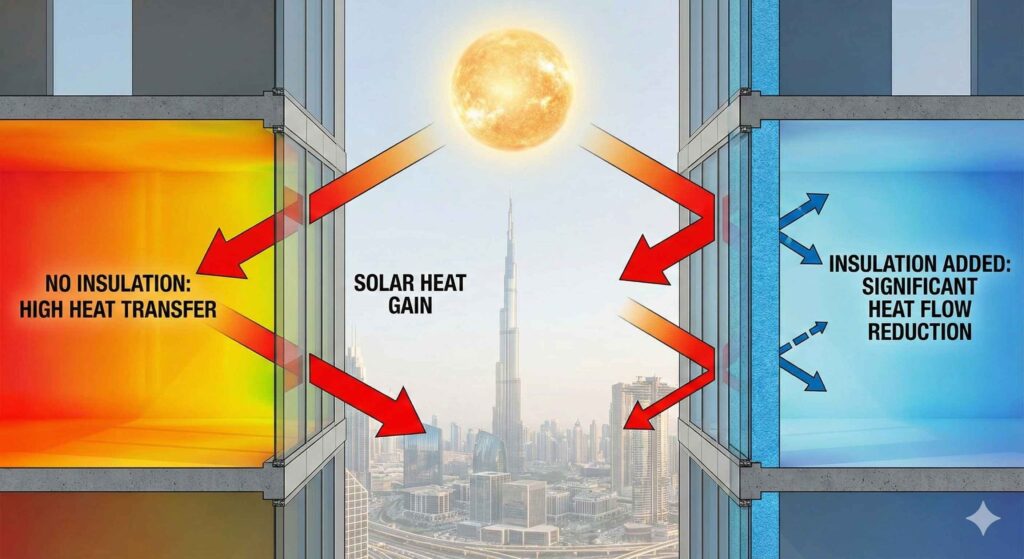

Thermal insulation in the UAE means materials and systems that reduce heat transfer through walls, facades, and roofs. In a climate where temperatures can cross 50°C, insulation has a direct impact on:

- HVAC load

- Energy bills

- Thermal comfort

- Façade performance

- Overall sustainability (LEED, Estidama, Al Sa’fat)

Because of this, Dubai Municipality, Abu Dhabi UPC, and Trakhees now enforce strict U-value limits across building envelopes.

Why Thermal Insulation Matters in the UAE

Effective thermal insulation in the UAE solves 4 major problems:

1. High Cooling Costs

Buildings in the Emirates spend 70–80% of energy on cooling.

Better insulation → lower bills → higher sustainability scores.

2. Scorching Heat & Solar Radiation

Wall temperature increases to 65–75°C due to direct exposure.

Without proper insulation, HVAC systems work harder.

3. U-Value Compliance

Authorities often require strict U-values:

- 0.23–0.30 W/m²K (typical walls)

- As low as 0.15 W/m²K for high-performance buildings

4. Space Limitations in Urban Projects

Architects often struggle with:

- façade thickness

- shaft and corridor limitations

- internal usable area loss

Selection of the correct insulation solves both technical and spatial complications.

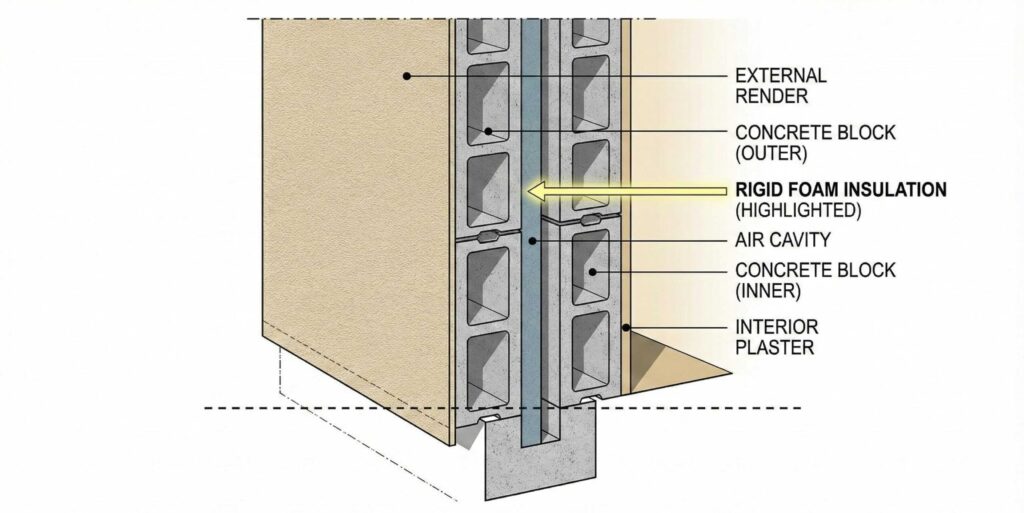

Types of Thermal Insulation Used in the UAE

Following are the most commonly used thermal insulation materials in the UAE:

a) EPS (Expanded Polystyrene)

- Affordable

- Medium performance

- Usually 50–100 mm required

b) XPS (Extruded Polystyrene)

- Higher compressive strength

- Good for façade & podium

- 50–120 mm commonly required

c) Rockwool

- Fire resistant

- Good acoustic performance

- Often 100–150 mm thick for compliance

d) PU Spray Foam

- High performance

- Expensive

- 40–60 mm typically required

Insulating Plasters & Advanced Coatings

Newer technologies mean better performance with lower thickness.

Useful for renovation and projects with strict space limitations.

U-Value Requirements for Thermal Insulation in the UAE

In order to meet Dubai Green Building Regulations (Al Sa’fat) and Estidama, most envelopes must fall under:

| Element | Typical Requirement |

| External Walls | 0.23–0.30 W/m²K |

| Roof | 0.15–0.20 W/m²K |

| High-performance buildings | ≤ 0.15 W/m²K |

Understanding these limits helps in choosing the right solution and thickness from the beginning.

Challenges Engineers and Architects Face

Engineers and Architects working on thermal insulation in the UAE have to deal with:

1. Limited façade thickness

High-performing insulation often requires 100–150 mm which is not always possible.

2. Conflicts between architectural and structural drawings

Insulation can interfere with cladding systems, MEP routing, and wall buildup.

3. Fire rating & durability

Materials must comply with UAE Fire Code, aging performance, and humidity resistance.

4. Cost vs. performance conflict

High-performance insulation systems can be costly and can create challenges in value-engineering.

How to Choose the Best Thermal Insulation in the UAE

When selecting insulation for Dubai or Abu Dhabi:

✔ Check U-value performance

Materials must meet code requirements without unnecessary thickness.

✔ Understand project limitations

Hotels, towers, refurbishments, and villas all have different constraints.

✔ Verify certifications

Make sure to comply with:

- Dubai Municipality

- DCL

- UAE Fire Code

- ASTM/EN standards

✔ Consider lasting performance

Humidity, expansion, contraction, and UV exposure should be kept in mind.

Cost of Thermal Insulation in the UAE

Approximate costs (material only):

| Type | Cost (AED/m²) | Notes |

| EPS | 12-25 | Most economical |

| XPS | 18-45 | Popular in façade & podium |

| Rockwool | 30-55 | Fire-resistant, acoustic |

| PU Foam | 35-75 | High performance |

| Advanced Coatings | 70-120 | High performance in thin layers |

Costs depend on thickness, brand, compliance, and installation.

Common Application of Thermal Insulation in the UAE

1. External walls

To meet U-value requirements and control heat gain.

2. Roofs

Roofs are critical because they are exposed to direct sunlight.

3. Podiums & parking areas

To reduce heat transfer to internal spaces.

4. Renovation projects

Where thickness is limited and energy upgrades are required.

Final words with a case example

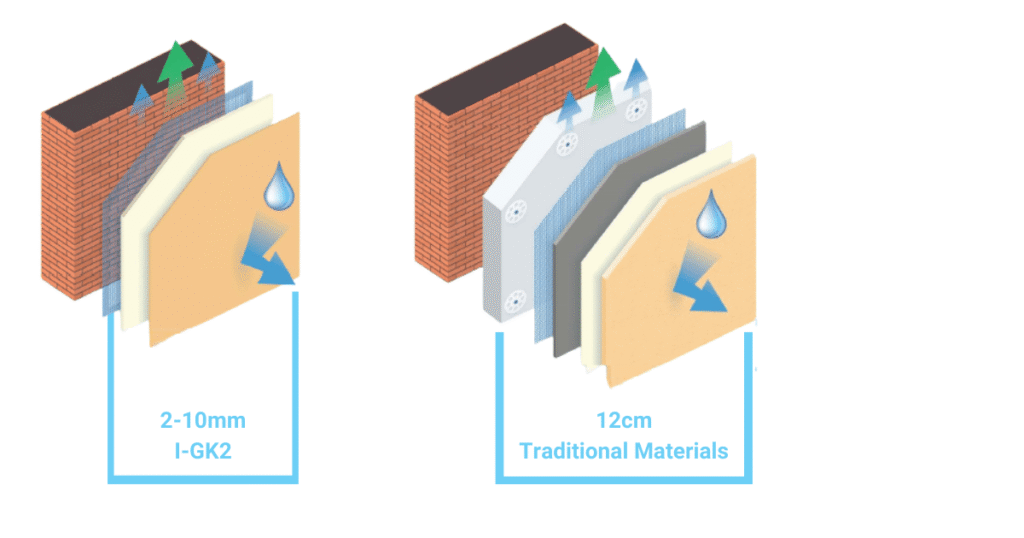

As we mentioned at the starting of this article, a new technology for Thermal Insulation that is entering the UAE market to solve the challenges of architects and engineers. This advanced nanotechnology is called I-GK2, a high-performance coating that can be used in place of the traditional EIFS system. It is a game-changer in achieving strict U-value requirements with minimum thickness.

Here’s a real case example:

A consultant asks:

“Can we achieve 0.15 W/m²K with ≤80 mm thickness?”

Traditional insulation answer: No

(Usually 100–120 mm required)

But I-GK2 said: Yes

(A modern nano-based technology achieve this with only 19mm.)

This shows the importance of looking beyond conventional materials when faced with spatial limitations.

Need support with your thermal insulation requirements?

Contact Flameco Group for a free consultation.